Thermal Imaging Using SWIR Camera Technology

All objects emit light in the infrared range. The hotter the object the more light that is emitted and the wavelength of the peak intensity moves to shorter and shorter wavelengths. This is demonstrated by looking at black body curves for various temperatures as can be viewed in this article: Black body radiation (sun.org)

Shortwave infrared (SWIR) is used in many applications for imaging objects that are greater than 100°C (> 373°K or >212°F). Above these temperatures, objects emit enough thermal emissions to be detected despite ambient lighting in the camera’s FOV. Though a Long-wave infrared (LWIR) or Mid-Wave infrared (MWIR) imager are typically used for thermal imaging, they can’t see through glass, quartz, or plastics used as safety barriers. They must also use exotic materials like silicon or germanium for lenses, limiting their utility for monitoring industrial processes. NIR-SWIR cameras, on the other hand, are used to monitor chemical recovery furnaces where quartz relay optics relay the image through 1-meter-thick walls. Remote monitoring of steel processing endpoint is a more cost-effective means of detecting when slag has started leaving the molten ore bucket as the emissivity of the slag is much brighter than the iron. And SWIR imaging ‘sees’ the defects inside hollow bottles coming out of the mold, while MWIR and LWIR only see the outside temperature of the bottles. A visible camera doesn’t see the defect either because the glass temperatures are too low to emit visible light from the defect.

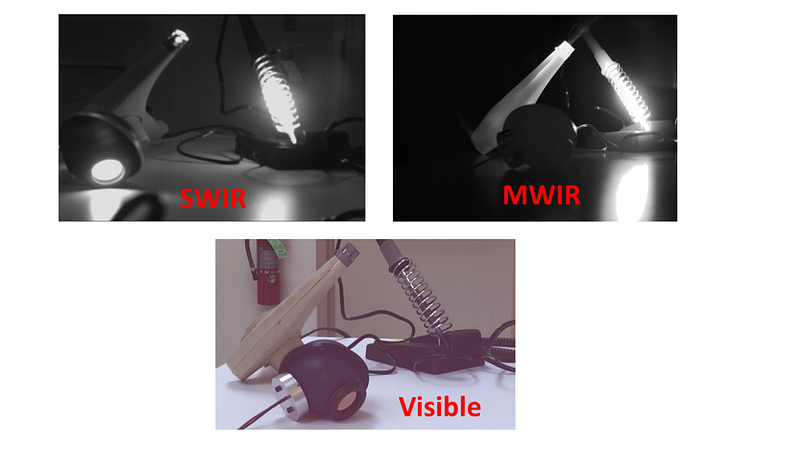

SWIR cameras also ‘sees’ reflected ambient light as well as the object’s thermally emitted light, enabling one to more easily differentiate objects. In this case one can see the electrical cords from the soldering iron and to also see the 1.3-μm light in the integrating sphere on the left of the image.

For machine-vision applications like metal coating, furnace monitoring or bottle inspection, use the Princeton Infrared Technologies (PIRT) 2-D camera the MVCam SWIR camera. It has the acquisition speed, the smooth sensitivity response curve, and the sensitivity to handle the task.

If the need is to image objects cooler than 100°C through windows or glass lenses, the deep cooled 1280SciCa2 may be the solution. By cooling the detector array below room temperature, its sensitivity is greatly increased. However, to improve selectivity for the thermal characteristics of the inspection object, it may be useful to image through a 1-μm wavelength long-pass filter to reduce visible reflections.

Be sure to contact the PIRT SWIR Testing Lab to discuss your SWIR application in depth and determine its best imaging solution.

1280SciCam

1280SciCam PIRT1280A1-12

PIRT1280A1-12 Custom Foundry Work

Custom Foundry Work